Plans For Building A King Size Platform Bed

Building a king-size platform bed is a manageable DIY project that can save a significant amount of money compared to purchasing a pre-made bed frame. It also allows for customization to suit specific needs and aesthetic preferences. Careful planning, accurate measurements, and a solid understanding of basic woodworking techniques are crucial for a successful outcome. This article will outline the essential steps and considerations involved in constructing a robust and aesthetically pleasing king-size platform bed.

Before commencing the project, it is imperative to thoroughly research and select appropriate plans. Numerous plans for building a king-size platform bed are available online, ranging in complexity and style. Consider factors such as the desired height of the bed, the amount of storage space required (if any), and the overall aesthetic you wish to achieve. Pay close attention to the materials list and ensure that all necessary tools and materials are readily available. A well-organized workspace will significantly contribute to the efficiency and success of the project.

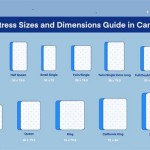

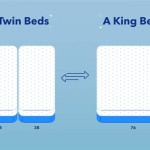

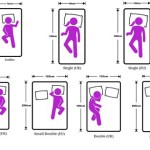

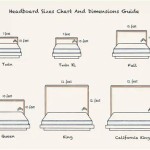

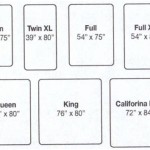

The standard dimensions of a king-size mattress are 76 inches wide by 80 inches long. These dimensions must be precisely accommodated in the bed frame design. However, it is recommended to add a small allowance (approximately ½ inch to 1 inch) on each side to ensure that the mattress fits comfortably and is easy to maneuver. This allowance will prevent the mattress from being too tightly squeezed within the frame, which can cause premature wear and tear.

Material Selection and Preparation

The choice of materials will significantly impact the overall cost, durability, and aesthetic appeal of the bed frame. Softwoods such as pine are generally more affordable and easier to work with, but they may not be as durable as hardwoods like oak, maple, or walnut. Pressure-treated lumber should be avoided for indoor furniture construction due to potential off-gassing of chemicals. Plywood is commonly used for platform beds due to its stability and affordability, but it is essential to select a high-quality plywood with minimal voids and a smooth surface.

Before cutting any lumber, meticulously inspect each piece for defects such as knots, cracks, or warping. Remove any loose knots and fill any significant voids with wood filler. Sand all surfaces smooth with progressively finer grits of sandpaper, starting with a coarser grit (e.g., 80 grit) and finishing with a finer grit (e.g., 220 grit). This will ensure a smooth and even surface for finishing.

Accurate measurements are paramount to the success of this project. Use a high-quality measuring tape and a square to ensure that all cuts are precise and that the frame is perfectly square. A miter saw is highly recommended for making accurate crosscuts, and a table saw can be used for ripping wider boards to the desired width. If using a circular saw, utilize a straight edge guide to ensure straight and accurate cuts.

Construction of the Bed Frame

The bed frame typically consists of four side rails and two end rails that are joined together to form a rectangular box. The joinery method used to connect these rails will significantly impact the strength and stability of the bed frame. Common joinery methods include using screws and glue, pocket screws, mortise and tenon joints, or lap joints. Pocket screws are a popular choice for their ease of use and strength, while mortise and tenon joints offer superior strength but require more advanced woodworking skills.

Before assembling the frame, apply wood glue to all mating surfaces. This will significantly strengthen the joints and prevent them from loosening over time. Use clamps to hold the pieces together while the glue dries. Ensure that the frame is square during assembly. Measure the diagonals of the frame to verify that they are equal. If the diagonals are not equal, adjust the frame until they are, and then tighten the clamps.

Once the frame is assembled, it is necessary to add support for the mattress. This is typically achieved by installing a series of slats that run across the width of the frame. The slats should be spaced evenly apart, typically no more than 4 inches to prevent the mattress from sagging. The slats can be attached to the side rails using screws or staples. Alternatively, a solid plywood platform can be used instead of slats. If using a solid plywood platform, ensure that it is adequately supported by additional framing members underneath to prevent sagging.

Adding Legs and Finishing Touches

The legs of the bed frame can be constructed from solid wood or purchased pre-made. The height of the legs will determine the overall height of the bed. Consider the desired aesthetic and the thickness of the mattress when determining the leg height. The legs should be securely attached to the frame using screws, bolts, or wood glue. For added stability, consider using metal brackets to reinforce the leg connections.

After the frame is fully assembled and the legs are attached, it is time to apply the finish. The choice of finish will depend on the type of wood used and the desired aesthetic. Common finishes include stain, paint, varnish, and polyurethane. Stain is used to enhance the natural grain of the wood, while paint provides a solid color finish. Varnish and polyurethane are clear protective coatings that provide durability and water resistance.

Before applying the finish, thoroughly sand all surfaces smooth with fine-grit sandpaper (e.g., 220 grit). Remove all dust with a tack cloth. Apply the finish in thin, even coats, following the manufacturer's instructions. Allow each coat to dry completely before applying the next coat. Lightly sand between coats with fine-grit sandpaper to remove any imperfections and create a smooth surface for the next coat. Apply at least two coats of finish for adequate protection.

Once the finish has completely dried, inspect the bed frame for any imperfections. Touch up any areas that need attention. Install drawer slides for additional storage, if desired. Place the mattress on the bed frame and ensure that it fits properly and is adequately supported. The bed is now ready for use.

The dimensions of individual components for the king-size platform bed are crucial for accurate cuts and assembly. The four main components consist of two side rails and two end rails. Calculating these dimensions involve subtracting the thickness of the end rails from the overall length to determine the side rail length, and similarly, subtracting the thickness of the side rails from the overall width to determine the end rail length.

After determining the main frame dimensions, the slats or plywood platform needs to be carefully considered, requiring detailed measurement and cutting. The spacing of the slats is equally important, ensuring even weight distribution and preventing mattress sagging. This step further emphasizes the need for detailed attention and calculation.

The planning phase is critical in identifying the necessary tools for the project. Basic tools might include a measuring tape, square, miter saw (or circular saw), drill, screwdriver, sandpaper, wood glue, and clamps. Advanced features such as a headboard or integrated storage will likely require additional tools. Having the right tools on hand ensures a smoother and more efficient building process.

While the general process remains similar across different plans, specific designs might introduce unique challenges. For example, building a floating platform bed or one with integrated storage needs careful planning and adjustment to the core framework. Moreover, designs that include upholstered elements demand proficiency in dealing with fabric and padding, which might not be part of a standard platform bed construction.

The primary aim is to construct a king-size platform bed that provides stable support and meets the intended design. Careful planning, precise cutting, and secure assembly are pivotal in achieving this objective. The selection of appropriate joinery methods is likewise important for producing a durable and long-lasting bed frame.

The completion of the project involves final checks to ensure that all elements are securely fastened and properly aligned. This might involve applying the finishing touches, such as filling nail holes, sanding rough edges, and applying the chosen stain or paint. The completed bed frame should be both aesthetically pleasing and functionally sound, providing a sturdy and comfortable sleeping surface.

King Sized Modern Platform Bed Printable Woodworking Plans Etsy

King Platform Bed Frame Plans Printable Woodworking Etsy

Diy King Size Platform Bed Howtospecialist How To Build Step By Plans

Diy Bed Frame Wood Headboard 1500 Look For 200 A Piece Of Rainbow

Free Woodworking Plans To Build A Viva Terra Inspired King Sized Vintage Fir Platform Bed The Design Confidential

Diy King Platform Bed Frame

Diy Platform Bed Frame Build Plan King Low Profile Minimalist Woodworking Plans Etsy

Tatami Inspired Platform Bed Plan King Size

King X Barn Door Farmhouse Bed Plans Her Tool Belt

Plan For King Size Platform Bed